Decade of Multi-Material Mastery

Ten years of custom display manufacturing for global retailers equips us to handle complex materials under highly customised requirements.

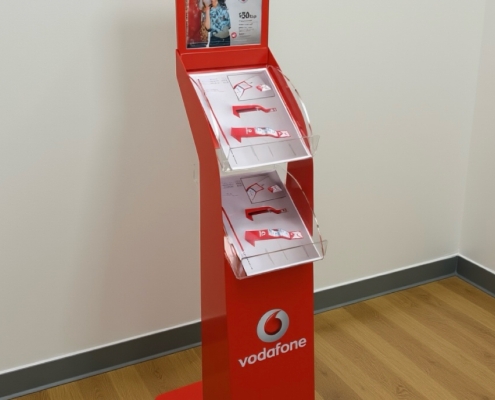

From acrylic bins to steel-wood panels, our engineers have resolved thousands of real-world cases. This expertise ensures reliable daily material integration:

– Metal mastery: Understanding cold-rolled steel/aluminium behaviour yields clean edges, reliable joints, and stable structures

– Cross-material integration: Retail displays (metal+acrylic+molded parts+wood) inform products like silicone-based trays, ensuring structural/aesthetic integrity

– Lighting expertise: Producing embedded lightboxes for North American pharmacies taught LED heat management. Today’s magnetic lights feature concealed modules and even diffusion.

Shop-Floor Confidence

While making custom acrylic displays for IKEA, we developed heat-bending tolerance control, later applied to curved stands (arc deviation <0.5°). Share a technical drawing for real-time material/structure advice. "Multi-material coordination" stems from production experience: fixture tuning, manual grinding, tolerance control, and on-site documentation.

Supply Chain Resilience

Years serving U.S./EU markets taught us to build redundancy into every BOM. Core materials (e.g., Korean/Taiwanese acrylic; Indonesian/Guangxi wood) are multisourced.

Export-grade packaging standards (compression/drop/vibration tested) ensure home goods survive ocean shipping.