Excellence Engineered In

After a decade in export manufacturing, one fundamental truth becomes clear: true quality is not merely inspected in; it’s engineered from the initial design phase. We are acutely aware of the essential concern of global clients: ensuring consistency between approved samples and mass production. Our approach is systematic: standardized processes control variables, precision equipment stabilizes output, and transparent data fosters trust.

Proactive Problem-Solving

In designing steel-wood shelving for a German retailer, we proactively simulated thermal and humidity cycles and adjusted connector tolerances to prevent warping. This design-driven methodology now characterizes all wood-composite product development.

Laser Precision:

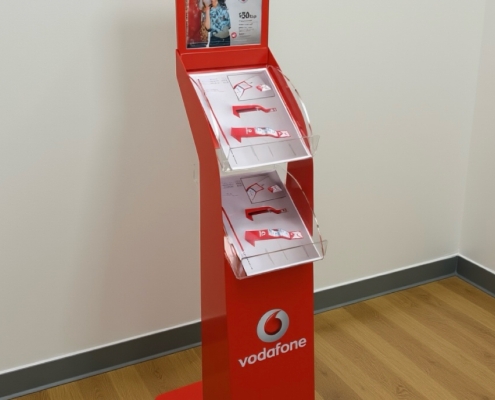

Daily calibrations within ±0.1mm guarantee consistent alignment, which is vital for perforated shelving and retail systems.

Material Integrity:

Japanese clients insist on absolute consistency. We have implemented strict protocols for sourcing single-coil steel, ensuring complete batch traceability and joint-free fabrication to maintain uniform quality.